Bridging the Gap: How Sulzer’s Pilot Services Turn Process Concepts into Commercial Success

- cemnar0

- Jul 29, 2025

- 2 min read

Introduction: The Critical Role of Sulzer’s Lab and Pilot Services

In the complex journey from a process concept to a full-scale industrial plant, the role of reliable pilot testing cannot be overstated. Sulzer’s lab and pilot services provide critical validation and optimization, enabling companies to bridge this vital gap with confidence.

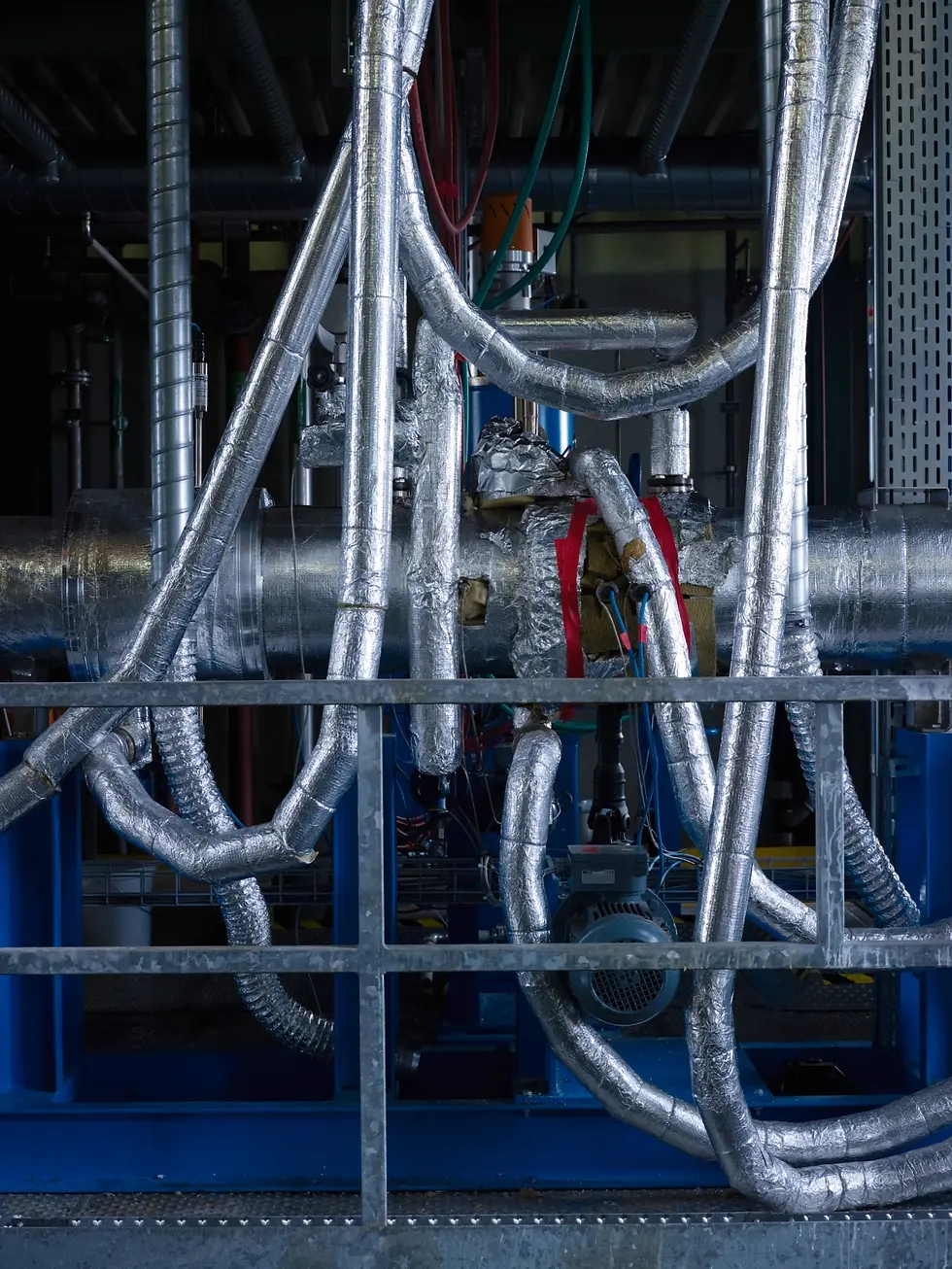

At Sulzer’s renowned IntecH pilot centers, located globally, our pilot services employ both stationary and mobile units designed to handle real customer feed materials under realistic operational conditions. This approach not only proves process feasibility but also minimizes scale-up risks, accelerates project timelines, and provides solid data for performance guarantees on industrial plants.

Why Choose Sulzer’s Pilot Services?

Sulzer’s integrated lab and pilot capabilities generate a trustworthy technical foundation that supports:

Process Feasibility Validation: Testing with your actual feedstocks ensures realistic results unattainable from simulation or literature alone.

Technology Selection and Design Optimization: Refinement of equipment choices, operating parameters, and configurations for maximum process efficiency.

Scale-Up Risk Reduction: Early identification of operational challenges like impurities, foaming, or phase separations to avoid costly surprises.

Accelerated Time-to-Market: By providing actionable data and performance guarantees, Sulzer’s pilot services reduce development cycles and support faster commercial launch.

Comprehensive Pilot Testing for Diverse Separation Technologies

Sulzer’s lab and pilot services cover a broad spectrum of process technologies including:

Distillation and Absorption: Critical tests for mixtures with impurities, unknown vapor-liquid equilibria, or high purity requirements.

EvapCare™ Evaporators: Precise evaluation of film evaporation performance for temperature-sensitive or viscous products.

OptimEXT™ Liquid-Liquid Extraction: Scale-up validation and optimization of complex extractor types and phase separations.

Our flexible pilot units, mobile or in-house, can be customized to your specific application and feed characteristics, providing you with practical, reliable, and scalable solutions.

Realistic Conditions With Mobile and Stationary Units

Sulzer’s pilot services utilize both mobile and stationary pilot units, offering you the best of both worlds:

Mobile Pilot Units: Bring the test rig directly to your site, enabling processing of fresh feed materials and immediate feedback on process performance.

Stationary Pilot Plants: Our IntecH centers in Switzerland and Singapore provide fully equipped, controlled environments for detailed experimentation and scale-up data collection.

This flexibility ensures maximum relevance of results, tailored technical support, and smooth transition from trial to plant.

Conclusion: Partnering with Sulzer for Successful Commercialization

In a competitive industry where process reliability and speed-to-market are paramount, Sulzer’s lab and pilot services offer unmatched expertise and infrastructure to help you turn innovation into reality.

By leveraging Sulzer’s pilot testing capabilities, you gain access to proven methodologies that reduce risk, optimize process performance, and underpin sound investment decisions closing the gap between concept and commercial success.

Ready to accelerate your project with Sulzer’s pilot services? Contact our technical team today to explore how a tailored lab and pilot program can unlock your process’s full potential.