From Lab to Plant: How Sulzer Scales Pilot Systems into High-Performance Skid-Mounted Solutions

- cemnar0

- Jul 18, 2025

- 3 min read

Introduction: Scaling Up Without Surprises

Scaling a chemical process from the lab to commercial operation is one of the industry’s greatest challenges. Many projects stall or fail when pilot data doesn’t translate, parameters drift, or time and cost spiral out of control.

That’s why global producers partner with Sulzer to scale processes smarter, faster, and safer.

With decades of experience in chemical scale-up and modular skid-mounted plant design, Sulzer provides a structured, proven pathway to commercial success from laboratory-scale testing to full-size, plug-in production units.

1. Bridging the Gap: From Proof of Concept to Commercial Production

Sulzer offers a dedicated test center network with pilot-scale systems that enable:

Feasibility studies

Product specification tuning

Equipment screening (e.g., extractors, evaporators, crystallizers)

Hybrid process modeling and validation under controlled conditions

Reliable decision-making data for CAPEX and scale

These pilot-scale experiments are backed by Sulzer’s process modeling tools (Aspen Plus, ProSim, etc.) and lab-scale testing forming the foundation for confident investment and systems engineering.

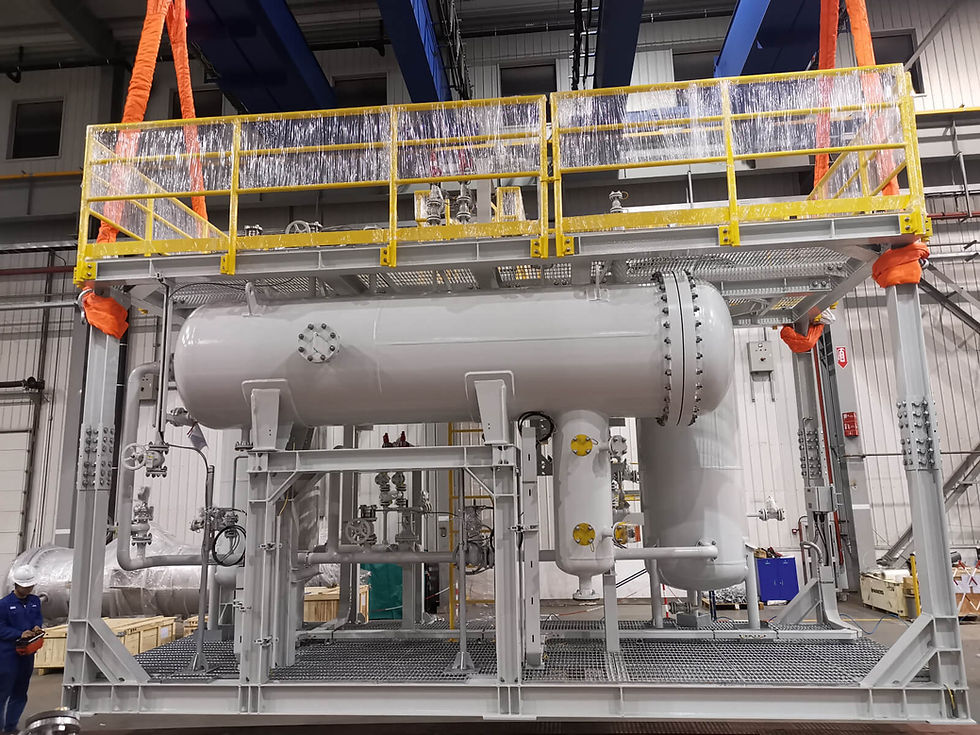

2. Modular Design Simplifies Scale-Up

When process validation is successful, Sulzer engineers use these results to design skid-mounted, full-scale systems that retain:

The same flow patterns, residence time, and thermal conditions

Inline process intensification (e.g. static mixing, reactive distillation)

Integrated safety and control systems

Optimized energy flows across evaporation, stripping, or separation modules

Because the data and design principles are already locked in, there’s less scale-up risk, quicker delivery, and guaranteed outcomes.

3. Real-World Deployment: From Trial to Turnkey Plant

Example: Amines and Solvent Swing Plant

A specialty chemical customer needed to validate product purity and EO conversion for a new amine-ether dual-purpose product line. Using Sulzer's pilot facility:

EO dosing, heat management, and safety protocols were tested

Product selectivity and purity were optimized via modular mixing design

A full-scale, skid-mounted swing plant was engineered and delivered in <12 months

The system operates catalyst-free, with >99.5% purity and low OPEX

Example: Pyrolysis Oil Upgrading Plant

A waste-to-chemicals customer used Sulzer’s pilot unit to test refining pathways for pyrolysis oils. From there:

Sulzer delivered a modular fractionation and purification skid capable of 53 tons/day throughput

The process, proven in pilot, was scaled with no yield losses or operational downtime

Result: Premium hydrocarbon product recovered from plastic waste

4. Integrated Validation = Better ROI and Faster Deployment

With Sulzer, you get a directly validated pathway from lab to field:

Phase | Sulzer Approach | Benefits |

⚗️ Pilot Testing | Sulzer test stairs, pilot labs, mobile units | Proof-of-concept confidence |

📐 Basic/Detail Engineering | Simulation models → 3D CAD → PFD/P&ID | Fast tracked layout and process integrity |

🏭 Skid Fabrication | Factory assembly & module pre-testing (FAT) | Accelerated startup, no onsite rework |

🚀 Site Startup | On-site installation, training, SAT support | Reduced commissioning time and greater safety |

5. Global Reach, Local Delivery

Sulzer has delivered over 250 skid-mounted plants worldwide, and continues to support customers in:

North America and Europe: specialty chemicals, solvents, pharma intermediates

Asia-Pacific: amines & glycol ethers, textiles recycling, CO₂ capture units

South America: bio-based fuels and extraction lines

Middle East & Africa: hydrogen purification, blending units, utilities and gas upgrading

Wherever your market, Sulzer can match your product — from lab sample to commercial specification.

Conclusion: Scalable, Modular, Reliable — the Sulzer Way

Scaling up doesn’t have to mean starting over. Sulzer offers an end-to-end process pathway from pilot validation to commercial operation, all within a tested, skid-mounted plant framework. Whether you’re commercializing a new product, improving an existing one, or entering a new region—the best path is modular, compact, and engineered by Sulzer.

Let’s bring your pilot project to life.

Contact Sulzer today to schedule a test campaign, simulation, or feasibility review—and discover the difference modular scale-up can make.