Sulzer Distillation Technology

Precision. Performance. Partnership.

Distillation is the most commonly applied separation process in the chemical and refining industries, and Sulzer has been at the forefront since 1940. Today, more than 100,000 columns equipped with Sulzer internals operate in over 500 different applications worldwide.

Explore a comprehensive range of distillation technologies designed to optimize separation and performance across industries

Batch distillation

Processes fixed volumes ("batches") of feed, making it ideal for multi-product or specialty chemical plants with changing feedstock compositions.

Using the Excelot™ platform, Sulzer provides tailored batch processes that can handle the most complex separation challenges, ensuring maximum yield and purity for even the smallest production runs.

Continuous single and multi-stage distillation

Single-stage (flash) involves a one-step separation, while multi-stage uses columns with trays or packing for repeated vaporization-condensation cycles to separate components with close boiling points.

Powered by DistilCare™, these systems utilize proprietary MellapakPlus™ packing and high-performance trays to minimize pressure drop and maximize energy efficiency.

Extractive distillation

Adds a high-boiling solvent to alter the relative volatility of components, allowing for the separation of mixtures with similar volatilities or azeotropes.

Integrated within the DistilCare™ framework, as example Sulzer’s GT-BTX™ technology provides world-class recovery of aromatics (BTX) from refinery and petrochemical streams.

Azeotropic distillation

Utilized when components form a constant-boiling mixture. An entrainer agent is added to form a new, lower-boiling azeotrope that can be easily removed.

DistilCare™ azeotropic systems are engineered to break these limitations with high precision while minimizing the energy required for solvent recovery.

Pressure swing distillation

Exploits the pressure-dependency of azeotropic compositions by operating two columns at different pressures to shift the azeotropic point.

A clean, solvent-free separation offered via DistilCare™. It uses advanced heat integration to reuse energy between columns, drastically reducing OPEX.

Reactive distillation

Reactive distillation combines chemical reaction and thermal separation into a single unit operation. By removing products as they are formed, the process overcomes equilibrium limitations, increases conversion rates, and reduces the need for downstream separation equipment.

Sulzer provides Reactive Distillation combines reaction and separation into a single, efficient unit operation

Specialized distillation

Distillation 2.0 lowering CAPEX and Carbon through Thermodynamic Intensification.

GT-DWC™ (Divided Wall Column): Consolidates a multi-column sequence into a single shell. Separate three-component mixtures into high-purity streams with up to 30% lower CAPEX and 35% energy savings compared to conventional setups.

VoltaSplit™ (Electrified Distillation): Decarbonize your separation train by replacing fossil-fueled steam reboilers with high-efficiency electric heating. A direct pathway to Net-Zero operations through industrial electrification.

Engineered for Extreme Efficiency

Our proprietary packings and trays minimize energy consumption, achieving up to 40% lower utility costs compared to conventional systems. We focus on maximizing theoretical stages with minimal pressure drop.

Global Project & Process Certainty

Leveraging centuries of collective knowledge, our experts deliver guaranteed process performance for even the most challenging separations, from retrofitting legacy columns to designing new units.

Unlocking Ultra-High Purity & Yield

Specializing in high-vacuum and challenging separation, we consistently meet the most stringent pharmaceutical-grade and specialty chemical purity requirements, reducing product loss and maximizing valuable output.

Comprehensive Lifecycle Partnership

Our commitment spans the entire plant lifecycle: from initial feasibility studies and pilot testing to fast-track revamps and 24/7 global field service, ensuring peak performance for decades.

Mass Transfer Components

Structured Packing

Over 50 years of design experience makes us the ideal partner. Our MellapakPlus™ packing is a proprietary, high-efficiency solution, often copied but never equaled.

Random Packing

We offer a one-stop solution with a range including traditional and high-performance rings like Nutter Rings™, I-Rings™, C-Rings™, P-Rings™, and R-Rings™ in metal or plastic.

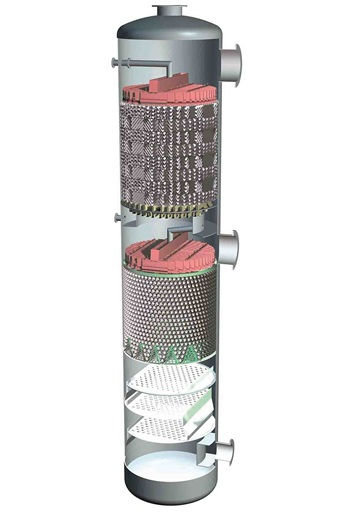

Trays

We hold the largest tray portfolio on the market, ranging from conventional fixed and movable valve trays to high-performance chordal downcomer, multi-downcomer, and the latest developments of ultra-system limit trays like VGPlus™ (one of the best high-performance trays ever tested at FRI).

Internals for Packed Columns

Even the best packing won't reach its full potential without appropriately designed internals. We ensure the perfect design for liquid distributors (e.g., VEP™ liquid distributor with the revolutionary splash plate), supports, and collectors.

Phase Separators and Statics Mixers

Gas-Liquid Separators

We offer an extensive range of innovative products for separating entrained liquid, starting with the cost-effective and versatile Sulzer KnitMesh™ wire mesh mist eliminators and including advanced devices like the Schoepentoeter Plus™ inlet devices, which are the first choice for efficient de-entrainment.

Liquid-Liquid Separators

Vapor-Liquid (Mist Eliminators): Removes tiny liquid droplets from a gas stream. KnitMesh uses a wire "sponge" to catch mist; Mellachevron™ uses zigzag plates to trap droplets via centrifugal force.

Liquid-Liquid (Coalescers): Separates two unmixable liquids (like oil and water). They force small droplets to merge into larger ones so they can settle and separate faster.

Mixers

Sulzer has pioneered the static mixing business for over 35 years. Static mixers (SMV™ static mixer) are tubular internals that produce desired mixing and dispersion effects as the fluid flows around motionless parts, offering high mixing efficiency combined with large turn-down processing capabilities.

Comprehensive Engineering and Technology Services

We combine our technologically advanced products with a full scope of associated services. Tell us your need, and leave the rest to us!

Process Studies: Energy saving, process optimization, moving columns, and troubleshooting.

Hydraulics Analyses: Debottlenecking, analysis of internals hydraulics, and maldistribution.

Engineering Studies: Mechanical strength analysis, vibration analysis, FEM, and CFD analysis.

Laboratory and Pilot Tests: Dedicated facilities for CO2 absorption, high-pressure testing (up to 50 bara), and gas/liquid/liquid separation.

Customer Hydraulic Design Software: SULCOL

SULCOL is our state-of-the-art tool provided to customers for the design and rating of mass transfer columns.

Structured and Random Packing: Hydraulic design and rating, including default packing efficiency and graphical capacity diagrams.

Tray Hydraulic Design: Design and rating for fixed and movable valves, one-pass and multi-pass designs, conventional downcomer designs, and comprehensive descriptions of the Sulzer tray portfolio.

Download our Technical Resources

Contact an expert

Our technical specialists are ready to help you find the optimal distillation solution for your specific application

%20(1).webp)

Jesus Rangel

Global Product Line Manager

"With over 20 years of experience in distillation systems, I'm here to help you maximize efficiency and achieve your process goals."

Select a Resource

Choose from 3 documents

Brochure

Process plants

18 page

Brochure

Chemical process industry

4 pages

Brochure

Separation technology for the chemical process industry

Overview

The chemical process industry has always been the driving force for Sulzer´s innovations. In the early 1960’s,

the stringent requirements for the purification of heat-sensitive fragrances led to the development of the Sulzer

Packing BX, which set a new standard for vacuum distillation and led to the development of many other

unique products.

24 pages

Fill in the form to download this resource

How distillation works

A step-by-step breakdown of the distillation process that enables precise separation of liquid mixtures

1

The liquid mixture is heated in a reboiler at the bottom of the distillation column. Heat is supplied to vaporize the components with lower boiling points.

Heating

As temperature increases, lighter components turn into vapor and rise through the column. The vapor carries separated components upward.

Vaporization

Inside the column, the rising vapor contacts descending liquid on trays or structured packing. Components redistribute based on their relative volatilities.

Contact & Mass Transfer

At the top of the column, vapors cool in a condenser. Lighter components condense first, creating pure overhead product.

Cooling & Condensation

2

3

4

2

Pilot and test facilities

Purity achievable

7

Workshops

Energy reduction

24/7

Turn Around Service

Services

A

B

C

Sulzer Advantage

Proven Process Solution Provider for complex and challenging separations

Full Service Provider for proprietary process equipment and plant solutions, backed by guaranteed performance

Provide solutions from design to operation

Unique technology portfolio and extensive application know-how

Unique experience in combining unit operations

Distillation is a fundamental separation process used to purify and separate liquid mixtures into individual components. It exploits the different boiling points of substances to achieve precise separation, making it essential in industries ranging from petrochemicals to pharmaceuticals.

The core principle: Heat a liquid mixture until it partially vaporizes, then cool and condense the vapor to separate components with different volatilities. Repeat this process to achieve the desired purity.

Distillation ensures high-purity products, efficient separation of components, and optimized energy use, making it essential for producing chemicals, fuels, and solvents.

Sulzer uses advanced column designs, proprietary internals, and hybrid technologies like GT-DWC (Dividing Wall Column) to reduce energy consumption and operational costs.

Our technologies serve:

-

Chemical processing

-

Petrochemical plants

-

Oil & gas refining

-

Renewable energy production

-

Hybrid technologies combine distillation with other separation methods (e.g., membranes, extraction) to achieve higher efficiency and lower energy consumption.

Yes, Sulzer designs tailored solutions based on your process requirements, including modular systems and proprietary equipment for optimal performance.

150+ Years Experience

Proven track record in chemical process engineering and equipment manufacturing.

Global Presence

Worldwide support network with local expertise and rapid response capabilities.

Quality Assurance

ISO certified processes and rigorous quality control for reliable, safe operations.